LN120 120Liters per day automatic liquid nitrogen generating equipment

- Price

- US $140000

- Model

- LN120

- MOQ

- 1 set

Item specifics

- Liquid nitrogen capacity

- 120Liters/day

- Liquid nitrogen purity

- 99.5%

- Dewar tank capacity

- 300Liters

- Power

- 11kw

- Cooling Water Consumption

- 11.4Liters/min,@27 deg c

- Power supply

- 415V-3phase-50HZ

- Dimensions (LxWxH)

- 2000X1800X1600mm

- Weight

- 500kg

Review

Description

LN120-120Liters per day,99.5% automatic liquid nitrogen generating equipment

ON-SITE LIQUID NITROGEN GENERATORS

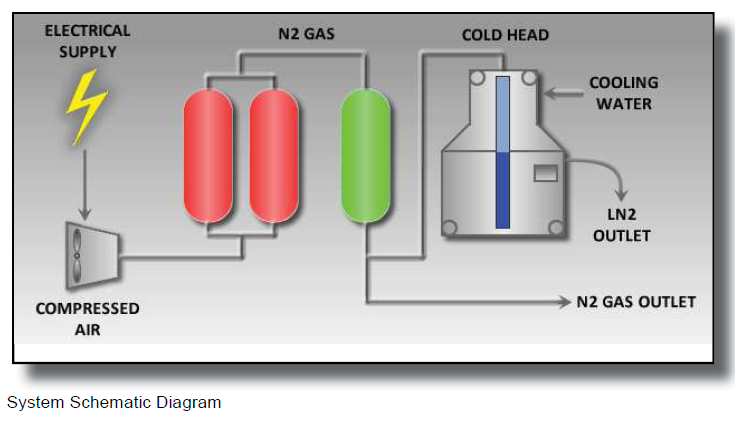

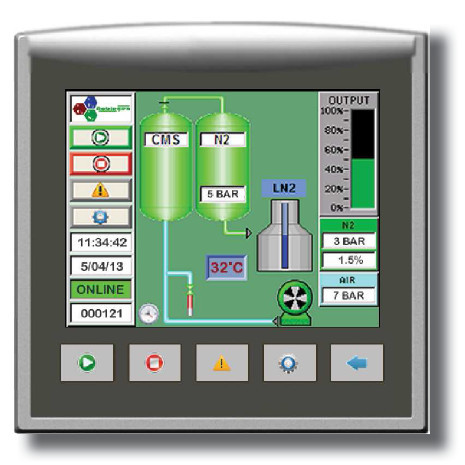

SCALA liquid nitrogen generating equipments are a simple plug and produce LN2 solution. An internal PSA nitrogen generator combined with a cryo-cooler, helium compressor and internal dewar all controlled through a colour graphic HMI touch-screen gives a fully auotmated system at the touch of a button.

THE NITROGEN LIQUIFIER

The SCALA liquid nitrogen generating equipment is based on the Gifford-McMahon technique of a cold-head design with the compression and expansion of helium to obtain low temperature cooling. The systems are specifically designed for applications where a certain gas must be liquefied and transferred to an internal storage vessel which can then be dispensed to the application.

PRODUCT FEATURES

Internal oil-free air compressor with autoclave (anti-bacteria) suction filter.

PSA nitrogen gas generator to give -60°c pdp nitrogen gas.

Sterile filter on nitrogen gas line to cryo-cooler.

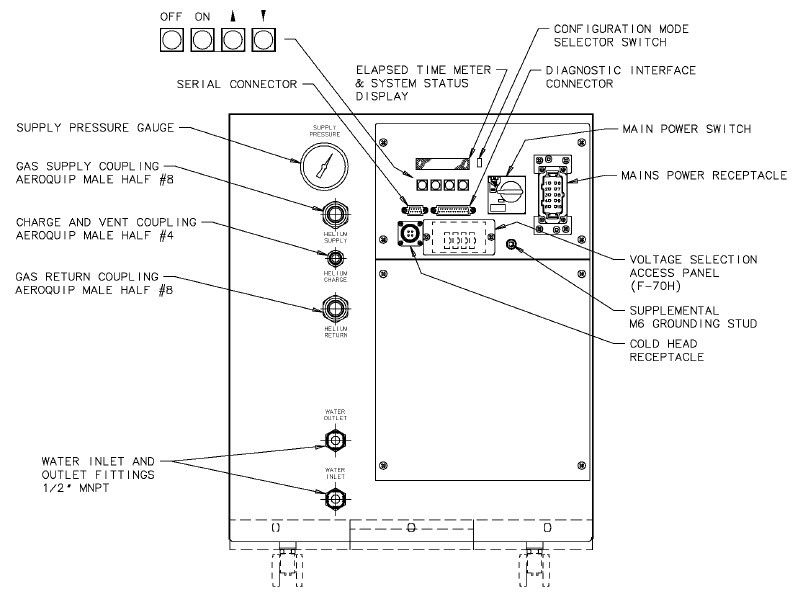

Reliable low maintenance helium compressor unit

Cryo-head is part of the dewar assemby for efficiency of production.

Liquid nitrogen outlet valve and transfer hose provided.

ADVANTAGES

Produce your own Liquid Nitrogen and eliminate deliveries.

Less waste – cold head keeps the dewar cold and reduces boil off compared to standard dewar.

Efficiency - Once internal dewar filled the system goes into standby, saving power.

Cost - Liquid nitrogen produced around 1/3rd the cost of delivered LN2.

Cleanliness – Closed loop system of nitrogen PSA, cryo-cooler and sterile filter ensures internal dewar is only filled with clean dry nitrogen gas and produces clean / pure liquid nitrogen.

Helium compressor made in USA

APPLICATIONS

-IVF clinics / hospitals for storage of samples.

NMR spectrometer to keep liquid helium cool and prevent boil off.

INSTALLATION

The SCALA liquid nitrogen generating equipment is a complete automated system supplied as a packaged piece of equipment either inside a floor mounted enclosure or a small skid mount design.

Firstly the cooling water should be connected to the ports shown on the side of the system – this should either be a mains water supply or a closed loop chiller specified and supplied by SCALA.

The system can be situated in its preferred location and connected to the mains supply using the cable supplied.As the system has already been fully commissioned and tested at our factory the START button on the screen can be pushed in order for the system to go into an initial start-up sequence:

1. PSA nitrogen generator achieves <1.0% oxygen content (approximately 30 mins).

2. The helium compressor / cold-head reduces the internal vessel temperature in order to start producing liquid nitrogen (approximately 4 hours).

Liquid nitrogen will be produced at the flow per day indicated on the data sheet for the specific product until the internal storage vessel is full. When full the generator will go into standby and will automatically re-start once the storage volume has dropped to pre-determined level.

LEVEL CONTROL

The internal liquid nitrogen storage vessel has a liquid level indicator with high and low set-points. The low level set-point can be adjusted by the customer for maximum efficiency depending on how much liquid is required, this means once the storage is full the system could remain in economy for longer and save power.

TECHNICAL SPECIFICATIONS | |||||||

Model | L/day | L/Hr | Storage Capacity | N2 Gas (L/min) | Electrical Supply | Power (KW) | Cooling water (L/min at 27°C) |

6 | 0.25 | 20 L | 3.3 | 230V | 1.5 | 1.7 | |

10 | 0.42 | 35 L | 5.5 | 230V | 2.2 | 2.8 | |

20 | 0.83 | 100 L | 11.0 | 230V | 4.0 | 4.5 | |

40 | 1.7 | 160 L | 13.0 | 415V 3PH | 5.5 | 6.0 | |

60 | 2.5 | 210 L | 33.0 | 415V 3PH | 7.5 | 7.6 | |

120 | 5.0 | 300 L | 65.0 | 414V 3PH | 15.5 | 11.4 | |

240 | 10.0 | 500 L | 130.0 | 415V 3PH | 31.0 | 20.0 | |