high efficiency compressed air pipeline filter for air dryer

- Price

- US $30

- Model

- F0045

- MOQ

- 1 piece

Item specifics

- Flow Rate

- 1.3m3/min

- Max Pressure

- 16bar

- Connection

- 1/2''NPT or BSP

- Filtration Grade

- M

- Particulate removal down to

- 1 micro

- Oil removal down to

- 0.1 ppm(w)

- Optional

- Inner automatic drain

- Optional Accessories

- Differential pressure gauge

Review

Description

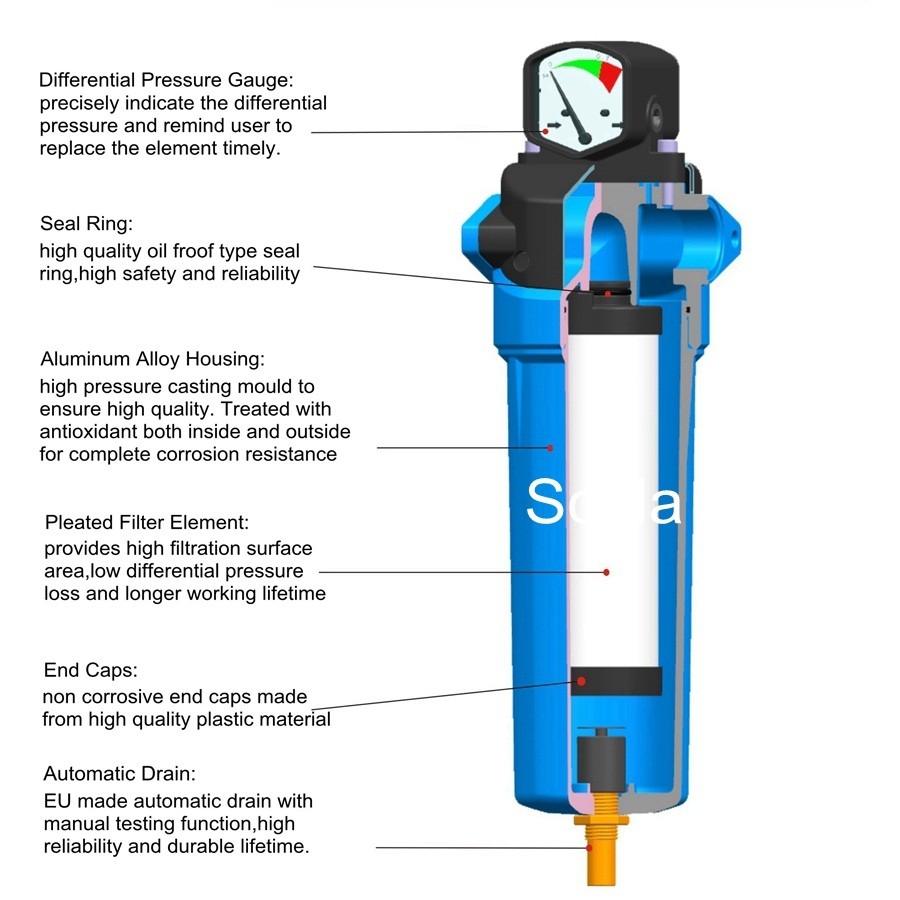

Compressed air contains harmful solid, liquid and vaporous contaminants that can damage pneumatic equipment, control and instruments. Removal of these contaminants is necessary to sustain equipment life and continue efficient production operation. Rust, scale and decay within compressed air system piping, and ambient air that contains gaseous and corrosive substances are common factor that contribute to the damaging effect of compressed air. Compressed air purification equipment must deliver high quality air with the lowest cost of operation.

Low pressure drop- Energy Efficient

Inner automatic drain with manual testing,differential pressure gauge

Inner threaded installation,easy to replace the element.

Pleated element, low pressure drop ,large filtration area.

Stainless steel and aluminum alloy hosing features high cooling effect.

Suitable for all compressed air application and all compressor type

Suitable for mineral and synthetic oil and oil free application

Silicon free ,safe for painting and surface coating applications

Electrophoresis treatment eliminating corrosion on internal and external head and bowl surfaces.

Scala elements are manufactured for lowest pressure drop and in accordance with International Standard for compressed air quality ISO8573.1:2001

Why choose SCALA Air Filter ?

SCALA filter is equipped with differential pressure gauge which can precisely indicate the differential pressure and remind user to replace the element timely.

Automatic drain with manual testing function. It has high reliability and durable lifetime. If the condensate water is not discharged timely, the oil and water may be brought into the downstream pipeline to cause contamination.

SCALA filter is equipped with differential pressure gauge which can precisely indicate the differential pressure and remind user to replace the element timely.

Automatic drain with manual testing function. It has high reliability and durable lifetime. If the condensate water is not discharged timely, the oil and water may be brought into the downstream pipeline to cause contamination.

SCALA's high efficiency filter element has the following advantages:

1. Deep Bed Pleating

Pleated filter elements provides a greater filtration volume than non-pleated.

The large surface area and the low velocity, increase the space for holding contaminants,which reduce the differential pressure cased by retention of solid particles. The service life increase with a result of lower running cost.

2. Adopted with stainless steel diamond mesh which has larger filtration area and less pressure resistance compared to circular hole mesh.

3. Adopted with heat and corrosion resistant polyester wadding instead of traditional form. Form tears under high operational temperature causing the broken pieces to be carried over down stream.

4. No Pull rod design, saving installation space and very easy to change the element.

Elbow piping from air inlet to element which has smaller pressure drop compared to right angle piping. Antioxidative and painting treatment on housing features high corrosion resistance.

Air leakage can cause energy loss,many micro leakages are not easily found, SCALA filters are 100% leakage tested.

TECHNICAL DATA

Filtration grade

Grade P - 3 micro general purpose particulate filter

Separator, filter, removal large amount of solid or liquid rust, abrasion particles.

Grade M- 1 micro,0.1mg/m3 general purpose coalescing filter

Removal of medium amounts of solid or liquid, fine contaminants, fine dust particle, small droplets and aerosols

Grade H- 0.01micro,0.01mg/m3 high efficiency colaescing filter

Removal of small amounts of solid or liquid,fine contaminants,fine dust particle,oil mist and aerosol

Grade C- 0.003mg/m3 active carbon filter

Removal of small amounts of gaseous, contaminants in particular oil vapor.

Correction Factor